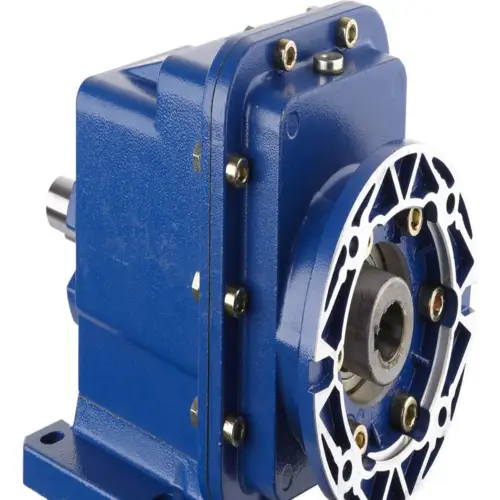

ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox For Servo Motor Steeping Motor

Our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox is a versatile reducer that offers small size, large output torque, high speed ratio, high efficiency, and reliable performance. The inner gear is made of low carbon alloy steel and undergoes carburizing quenching and grinding or nitriding process. The planetary gearbox is available in both spur gear and helical gear configurations, which can be selected according to the needs of the application.

Model Selection

Our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox is available in different models to meet the requirements of various applications. Customers can choose the right precision reducer based on their specific needs.

Range Of Planetary Gearbox

Our ZD High Precision Low Backlash Spur or Helical Gear Planetary Speed Gear Reducer Gearbox is suitable for use in a wide range of applications, including servo motors and stepping motors. It is designed to provide reliable performance and high efficiency even in demanding industrial environments.

Customized Product Service

We offer customized product services to meet the specific needs of our customers. We welcome customers to provide us with drawings and samples, so we can design and manufacture products tailored to their requirements.

Other Related Products

Our company supplies a wide range of products for industrial use, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We are committed to providing high-quality products, preferential prices, and considerate services to meet the needs of our customers.

FAQs

What type of motors do you produce?

We currently produce Brushed Dc Motors, Brushed Dc Gear Motors, Planetary Dc Gear Motors, Brushless Dc Motors, Stepper motors, Ac Motors and High Precision Planetary Gear Box. You can find specifications for these motors on our website, or you can email us to recommend motors based on your specific requirements.

How do I select a suitable motor?

If you have motor pictures or drawings to show us, or you have detailed specs like voltage, speed, torque, motor size, working mode of the motor, needed lifetime and noise level etc, please do not hesitate to let us know, then we can recommend suitable motor per your request accordingly.

Do you offer customized services for your standard motors?

Yes, we can customize the voltage, speed, torque and shaft size/shape of our standard motors. We can also add wires/cables, connectors, capacitors, or EMC to meet your specific requirements.

Do you offer individual design services for motors?

Yes, we offer individual design services for our customers. However, mold development costs and design charges may apply.

What is your lead time?

Our regular standard products typically require 15-30 days, while customized products may take longer. However, we are flexible on lead times and will work with you to meet your specific orders.

All the content of this page is from the Internet and is only meant for reference purposes for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks mentioned in the content. Our replacement parts are designed to perfectly adapt to the original spare parts. If you need to buy original spare parts, please contact the original factory or supplier.

Performance Characteristics of Planetary Gearbox

- High torque transmission capabilities: Planetary gearboxes offer excellent torque transmission due to their design.

- High precision and efficiency: The arrangement of gears in a planetary gearbox allows for efficient power transmission with minimal loss.

- Compact and lightweight: Planetary gearboxes have a compact design and are lightweight, making them suitable for various applications.

- Low backlash: Planetary gearboxes have low backlash, ensuring precise movement and positioning.

- Ability to handle high speeds: Planetary gearboxes can handle high input and output speeds, making them versatile for different applications.

Types and Characteristics of Planetary Gearbox

There are several types of planetary gearboxes, each with its own unique characteristics:

- Inline Planetary Gearbox: This type of gearbox has a coaxial input and output shaft, making it suitable for applications where space is limited.

- Right Angle Planetary Gearbox: This gearbox has a right angle input and output shaft arrangement, allowing for flexibility in design and installation.

- Orthogonal Shaft Planetary Gearbox: With its orthogonal input and output shafts, this gearbox provides efficient power transmission in a compact design.

Advantages of Planetary Gearbox Made of Different Materials

Planetary gearboxes can be made of various materials, each offering its own advantages:

- Steel Planetary Gearbox: Steel gearboxes are known for their high strength and durability, making them suitable for heavy-duty applications.

- Aluminum Planetary Gearbox: Aluminum gearboxes are lightweight and provide good resistance to corrosion, making them ideal for applications where weight is a concern.

- Composite Planetary Gearbox: Composite gearboxes offer a combination of strength and light weight, making them suitable for applications where both factors are important.

Application of Planetary Gearbox

The versatility of planetary gearboxes allows them to be used in various fields:

- Automotive: Planetary gearboxes are used in automotive transmissions for efficient power transmission.

- Aerospace: Planetary gearboxes are utilized in aerospace applications for their high precision and reliability.

- Industrial Robotics: Planetary gearboxes are commonly found in industrial robots, providing accurate movement and positioning.

- Wind Turbines: Planetary gearboxes are used in wind turbines to convert the low-speed rotation of the blades into high-speed rotation of the generator.

- Medical Equipment: Planetary gearboxes play a crucial role in medical equipment, ensuring precise and reliable operation.

Future Development Trends and Opportunities

Planetary gearbox products have a promising future with the following development trends and opportunities:

- Increased demand for automation in various industries will drive the need for advanced planetary gearboxes.

- The growing renewable energy sector will create opportunities for planetary gearboxes in wind turbines and solar power systems.

- Advancements in material technology will lead to the development of more efficient and lightweight planetary gearboxes.

Choosing a Suitable Planetary Gearbox

When selecting a planetary gearbox, consider the following aspects:

- Load Requirements: Determine the torque and speed requirements of your application to choose a gearbox that can handle the load.

- Ratio Selection: Select a gearbox with the appropriate gear ratio to achieve the desired output speed.

- Type of Gearbox: Choose the type of planetary gearbox that best suits your space and design requirements.

- Environmental Factors: Consider factors such as temperature, humidity, and contamination to ensure the gearbox can withstand the operating conditions.

- Maintenance and Durability: Evaluate the maintenance requirements and expected durability of the gearbox to ensure long-term reliability.

In summary, planetary gearboxes offer high torque transmission capabilities, high precision and efficiency, compact design, low backlash, and the ability to handle high speeds. There are different types of planetary gearboxes, each with its own characteristics. The choice of material in the gearbox affects its strength, weight, and corrosion resistance. Planetary gearboxes find applications in automotive, aerospace, industrial robotics, wind turbines, and medical equipment. The future of planetary gearbox products is promising, with opportunities in automation, renewable energy, and material advancements. When selecting a gearbox, consider load requirements, ratio selection, type of gearbox, environmental factors, maintenance, and durability.

Author: Dream